Welcome to Our Website

Phone Number:

08045804046Contact Time:

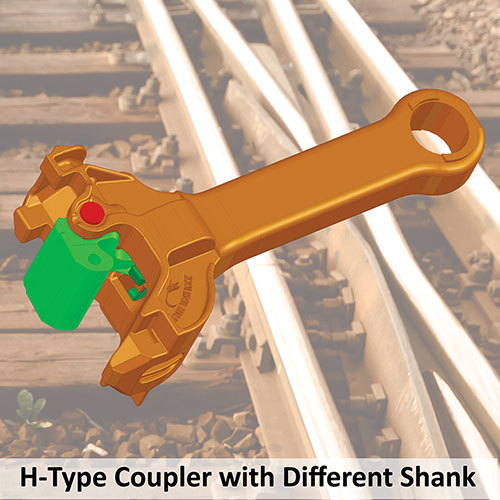

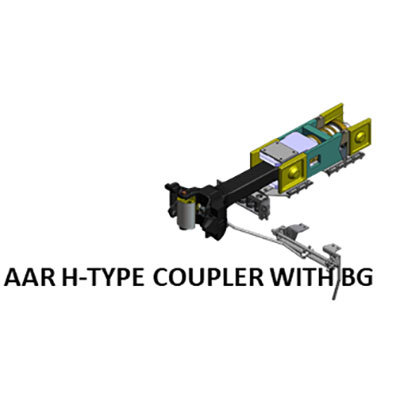

Mon-Sat: 9.00-18.00H-Type Coupler with Different Shank

Product Details:

- Technics Forged

- Weight Approximately 2.5 kg (Typical, varies with shank size)

- Color Silver Grey

- Technology Hot Rolled and Precision Machined

- Type H-Type Coupler with Different Shank

- Material High Grade Mild Steel

- Dimensions Length varies (150 mm to 300 mm), Shank sizes available in multiple standards

- Click to View more

X

H-Type Coupler with Different Shank Price And Quantity

H-Type Coupler with Different Shank Product Specifications

- CNC Machined for Accurate Fit

- Silver Grey

- H-Type Coupler with Different Shank

- Forged

- Around 125-135 HB

- Length varies (150 mm to 300 mm), Shank sizes available in multiple standards

- Smooth, Shot Blasted

- Approximately 2.5 kg (Typical, varies with shank size)

- Anti-Rust Coated

- Hot Rolled and Precision Machined

- High Grade Mild Steel

Product Description

H-type coupler with different shank mechanically joins separate nearby vehicles together to form a train. It also provides energy absorption during connection and services. In addition to this, our offered product is made to slide into the Coach's draught gear pocket and absorb dynamic energy in both draw and buff modes. H-type coupler with different shank offers a way to mechanically join separate nearby vehicles to form a train. It can be found at each vehicle's ends. The truck may travel independently to account for track curvature and elevation variation while keeping connected together when coupled with a coupler from a nearby car.

Rugged Build for Reliable Performance

This H-Type Coupler features a robust construction from high-grade mild steel, processed through drop forging and hot rolling for superior strength. Its surface is smooth and shot blasted, finished with a high-quality anti-corrosion coating, ensuring long service life even in harsh operating environments.

Versatile and Customizable Design

Designed to suit various railway and industrial applications, the coupler comes with different shank sizes to accommodate diverse requirements. Precision CNC machining guarantees accurate fits, while the silver-grey anti-rust finish provides both functionality and attractive appearance.

Strict Compliance and Superior Safety

Adhering to IS: 8610 and RDSO standards, these couplers are rigorously tested, ensuring optimal safety and reliability. Each unit is built to seamlessly integrate with multiple rail carriage and wagon models, offering dependable connectivity under heavy loads and high temperatures.

FAQ's of H-Type Coupler with Different Shank:

Q: How is the H-Type Coupler with Different Shank manufactured?

A: The coupler is produced using a drop forging process combined with hot rolled mild steel. It is then precision CNC machined to ensure dimensional accuracy and strength, followed by shot blasting and application of an anti-corrosion coating for lasting durability.Q: What benefits does the special anti-corrosion coating provide?

A: This specialized coating offers high resistance to corrosion, significantly extending the coupler's service life even in challenging environments. It also enhances the overall strength by protecting the underlying metal from rust and environmental damage.Q: Where can the H-Type Coupler be used effectively?

A: The coupler is designed for application in railway track fittings and heavy industrial coupling, making it suitable for connecting different rail carriages, wagons, and heavy-duty transport assemblies in industrial sectors.Q: What shank sizes and dimensions are available for this coupler?

A: Several shank sizes conforming to multiple standards are available, with coupler lengths ranging from 150 mm to 300 mm. Customization options are possible based on specific operational requirements.Q: When should a high tensile strength coupler be used?

A: A high tensile strength coupler, like this one with a minimum of 450 MPa, is ideal for situations involving substantial loads, repeated impacts, or harsh working conditions where durability, safety, and reliable performance are critical.Q: What is the typical packaging for the H-Type Coupler?

A: Packaging options include secure gunny bags or sturdy wooden crates, protecting the couplers from damage during transportation and storage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email