Welcome to Our Website

Phone Number:

08045804046Contact Time:

Mon-Sat: 9.00-18.00BEC is considered as one of the largest Foundry and Fabrication Shops in Central India with ISO 9001:2000 certification alongside the following features:

- Produce all sorts of cast iron and steel castings in three states such as proof machined, as-cast, and fully machined.

- Manufacturing capacity of 12000 tonnes per annum for ferrous castings and 14000 tonnes per annum for fabrication.

- Serves all major areas, including forging companies, steel plants, mining, heavy earth moving, pumps, mineral processing, valves, railways, cement plants, defense, oil, power generation, and non-ferrous industries.

- Improved infrastructure enables for speedy and efficient completion of all tasks. Our foundry has all the essential infrastructure to make and deliver high-quality Fabrications and Castings on time to ensure complete client satisfaction. It includes in-house die production using casting simulation modeling, 5S implementation, No-Bake System Molding Shop, Direct ARC Furnace Melting Shop, integrated assembly, fabrication, and machining facilities.

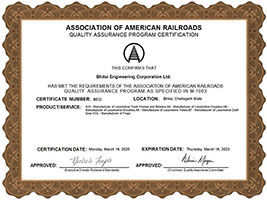

- Certifications include the following:

- ISO certificate

- Association of American Railroads- AAR M 1003 Certificate

- Railways Class A Foundry Certificate from Research Design & Standards Organization (RDSO)

- Railways certified Vendor Certification for Casnub Bogie and components, Truck Frame Assembly for EMD locomotives, CMS Crossings, Coupler Body, Co-Co Bogie, Draft Gear for Freight Wagons, Flexi-coil and Tri-Axle Bogie Frames, High capacity Draft Gear, HTCB Coupler, CS Bolster for BG Locomotives, etc.

- Ministry of Commerce and Star Export House (GOI)

- Ordnance Factory, BEML, Rites, NTPC, SAIL, Lloyds, Neyveli Lignite Corporation, BHEL, and others have certified us.

- A dedicated project control team, engineering group, and skilled workforce strive to offer the best service in the industry. It also helps us attain relevant experience through participation in rail projects worldwide with local and industry knowledge.

- Our products have an excellent reputation worldwide due to their high quality and on-time delivery. We have many customers in the United States, South Africa, Europe, Ukraine, Russia, Kenya, and CIS countries.

We offer our clients dependable, long-lasting, and tried-and-true solutions at BEC. We assist them in completing their project on budget and on time.

We provide worldwide clients with a

comprehensive range of train services and products in railways. We also

offer many important below-rail asset manufacturers in the United States

and other countries, including:

|

|

|

Among our esteemed customers (Railways) are the following:

- BESCO

- Chittranjan Locomotive Works

- Diesel Locomotive Works

- Electro Motive Diesel Inc, USA

- Indian Railways

- Jindal Rail Division, Delhi

- Metro Rail, Kolkata

- National Railway Equipment Company, USA

- Progressive Rail Incorporated (PRS), USA

- Rv Rail Products Pvt. Ltd

- Wheel & Axle Plant, Bangalore

Apart from those mentioned above, we have developed and are constantly exporting to the United States various components and equipment for the railways, defense, shipping industry, steel, cement, and other important industrial sectors at our Raipur Plant. For your convenience, we've attached an updated presentation. Under the following solutions, we have created specialist items for mining and material handling: -

- Bucket: We provide complete design, production, and maintenance for Bucket solutions for Shovels and Excavators, Rope and Dragline shovels, and Hydraulic Excavators as per the requirements of our customers.

- Breaking and Crushing: The Feeder Breakers at our unit have a capacity of up to 500 TPH and can reduce the material size to -100/-200 microns.

- Bulk Material Handling: We provide OEMs with turnkey manufacturing solutions for heavy-duty material handling machines such as Stackers/Reclaimers, Bridge Reclaimers, Ship Loaders/Unloaders, Wagon Tipplers, and other similar machines.

Further,

- We want to negotiate a partnership or an alliance with the prestigious company of our clients to produce, distribute spares and assemble the undercarriage to users and OEMs in India. Our company will expand capacities and facilities to meet the manufacturing and quality needs of any company as part of our Manufacturing Partnership.

- The company of our clients might be a technical collaboration for us, assisting them with technical know-how, technical specifications, and manufacturing patterns for undercarriage parts and assemblies.

- Our clients can form a joint marketing and sales team with us in India and other territories.

- We can also work as a distributor for the products of our customers in the designated zone.

- Our customers and we can form a joint venture in India to produce undercarriage parts and sub-assemblies for India and emerging markets.

Download Brochure

Certification

|